7 sustainable fashion technologies for eco-friendly production

From augmented reality dressing rooms to green materials, discover the latest innovations transforming fashion retail and how forward-thinking brands are already capitalizing.

Share on

These seven tech trends in apparel production make fashion more sustainable. Learn more about virtual sampling, alternative textiles, fashion on-demand, 3D mobile body scanning.

These seven tech trends in apparel production make fashion more sustainable. Learn more about virtual sampling, alternative textiles, fashion on-demand, 3D mobile body scanning.

The $ 3.5 trillion fashion industry is one of the largest business sectors in the world. It is also one of the most wasteful producing 20% of global water waste and 10% of carbon emissions. Additionally, nearly three-fifths of all clothing produced ends up in incinerators or landfills within a few years of being manufactured. The equivalent of one garbage truck of textiles is landfilled or burned every second. While clothes are an everyday necessity and fashion is a form of personal expression, current textile waste far outweighs the benefits of the industry. Without sustainable fashion production solutions, the trend seems doomed to continue.

For decades, profits have been put ahead of concern for sustainability in the fashion industry. Luckily, changes in mindsets are emerging that have the ability over time to flip this model. Combined with exciting new technology in fashion, growing concern over fashion’s environmental impact is paving the way towards a more sustainable apparel business model and ecosystem.

How can the fashion industry become more sustainable? How sustainable fashion technology reduces fashion’s impact

Today’s consumers are paying close attention to the businesses they shop with in an effort to minimize the impact their purchases have on the world. Sustainability trend, slow fashion movement, ethical fashion – web searches for industry’s eco-friendly goods have risen by more than 70% over the past five years. According to McKinsey, three in five now claim environmental impact is an important factor in making purchasing decisions. Apparel industry technology trends are beginning to reflect this, with the development of new, sustainable fashion technology focused on tackling the causes behind the industry’s struggles.

So how can clothing companies be more sustainable? From solving the industry’s size and fit issues, to increasing personalization, and promoting re-use when possible, by embracing new technologies in fashion businesses can create the sustainable future their customers desire.

3DLOOK

Get in touch to find out how 3DLOOK’s body scanning technology can help your fashion business to provide personalized shopping experiences for your customers, increase conversions and reduce returns.

Sustainable fashion technology affecting materials, products and consumer experience promise to have an enormous impact on reducing waste over the next decade. Eco-conscious companies are already making changes to materials that add longevity and require fewer resources. Additionally, new opportunities for recycling garments lean toward a circular fashion economy.

Green fashion technology: 7 exciting sustainable fashion innovations reducing fashion’s environmental impact

Here is the list of seven exciting sustainable fashion innovations transforming production and recyclability that will deepen your knowledge on how to create a greener fashion supply chain.

1. 3D Virtual Sampling

In the past, physical samples have been a necessity in the design and buying and selling lifecycle. These samples provide both designers and the retail buying teams an accurate representation of the product, but one finished style can require 20 or more samples before production. However, as 3D technology evolves, virtual sampling already enables a digital full line review which reduces waste in both design and product development.

3D design sweater by Tommy Hilfiger in BrowZwear.

Image credit: BrowZwear

By 2021, all of Tommy Hilfiger’s design processes — from sketching through sampling and showrooming — will be done with 3D design. 3D virtual sampling brings the same concept to a screen with virtually no waste during the process. Another major advantage of this transformative sustainable fashion innovation is cost reduction associated with the materials and time related to creating physical samples. Virtual sampling can also help to digitize a consumer-focused on-demand manufacturing model.

2. Alternative Textiles

Materials commonly used in clothing take considerable resources and often degrade slowly. The creation of one cotton shirt requires the same amount of water as one person drinks in 2.5 years. Synthetic materials like nylon and polyester use less water during production but emit dangerous greenhouse gases.

However, the development of sustainable technologies for fashion and textiles that are recyclable, regenerative, reusable and responsibly sourced are providing alternatives. Some eco-friendly textile alternatives include recycled fibers and fibers extracted from agricultural waste products such as leaves and rinds. These new textiles offer options that produce less waste during production, are long-wearing, and biodegradable. Natural fibers like hemp, bamboo, and ramie are widely used as cotton alternatives. Brands like COS and H&M choose cupro, as it is produced from cotton linter, waste from a cotton plant, through a closed-loop technology.

Designers like Stella McCartney have pioneered closed-loop and sustainable business models using innovative materials such as bio-based fur. This 37% plant-based fabric consumes up to 30% less energy and produces up to 63% less greenhouse gas than conventional synthetics. Also worth mentioning an innovative eco-friendly alternative to leather, Piñatex, made from pineapple leaf fiber by Ananas Anam, and muskin, the vegetable leather made from mushrooms.

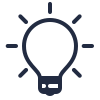

Natalia Vodianova, supermodel and 3DLOOK’s advisor, in Stella McCartney’s new bio-based faux fur.

Image credit: Vogue

3. Automation and Fashion on Demand

Fast fashion businesses and mass production models have contributed to vast amounts of waste and returns. Marketers pushed mass consumption on consumers and this mindset fueled this model over the 1990’s and 2000’s. But as the rise of e-commerce and social commerce over the last decade has created an entirely new business model, consumers are now in the driver’s seat, and they care a lot about both personalized experiences and the planet. On-demand design and manufacturing will play a significant role in the future of fashion. Instead of producing clothes and then selling them, the items are ordered then produced. While today single and small batch production costs more to manufacture, automation and innovation in manufacturing combined with the money saved with reduced returns and guaranteed sales will offset these costs over time.

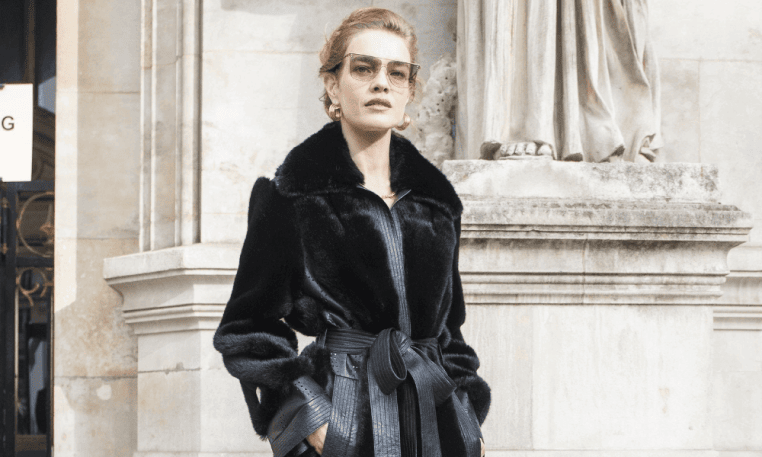

Mobile Tailor

Allows custom fashion businesses to switch fully online and save time and costs associated with manual measurements and face-to-face appointments.

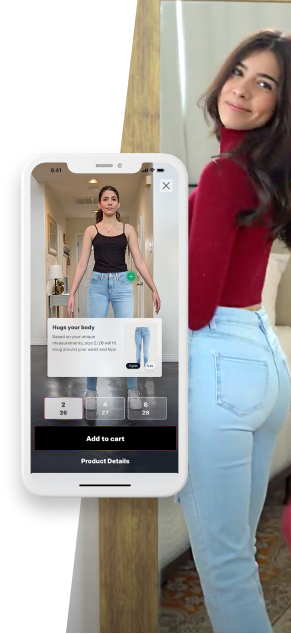

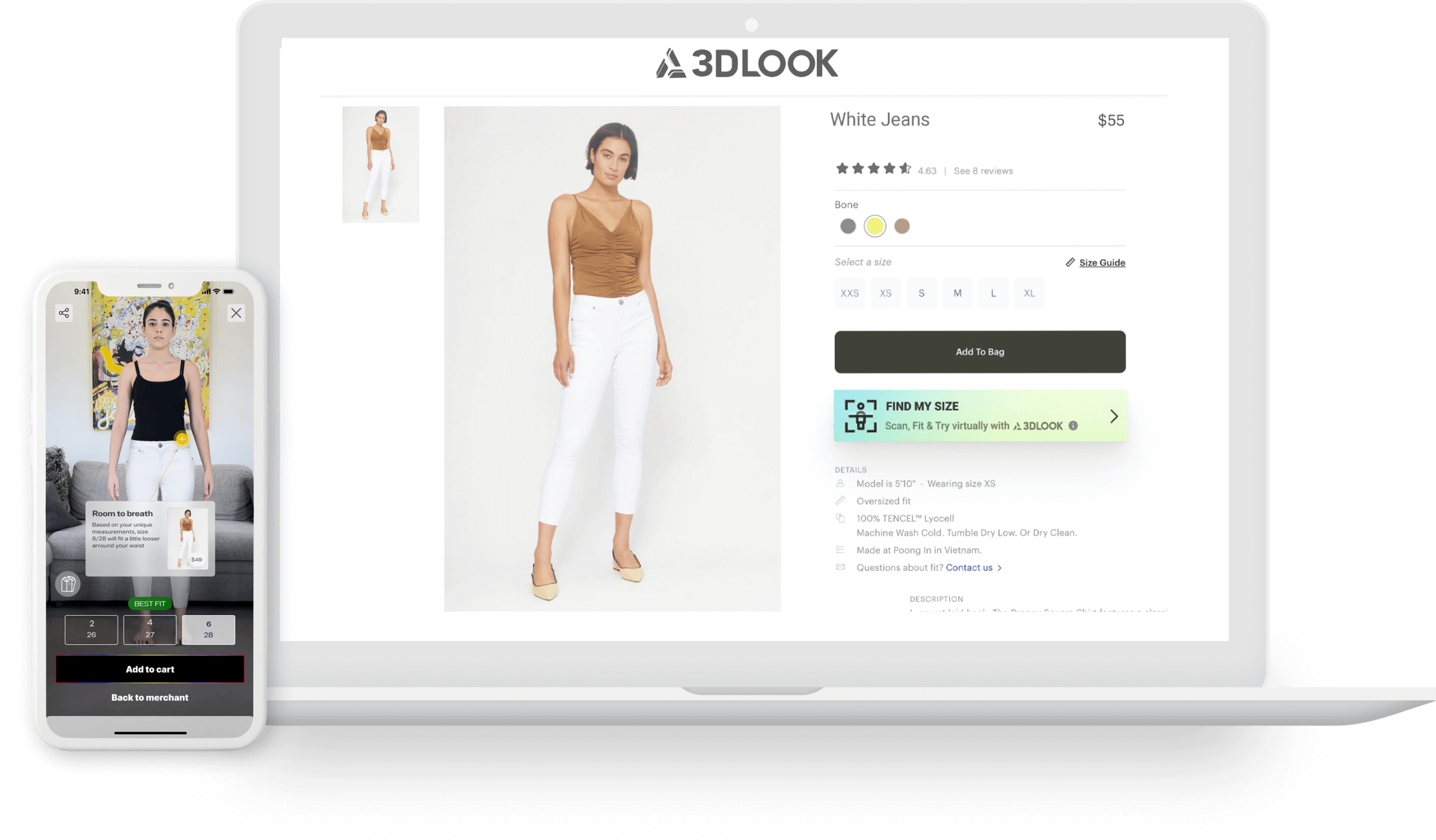

4. Mobile Body Scanning

Designers and manufacturers decide the dimensions of garments based on extremely limited information designed to “average” body shapes, leaving the bulk of consumers wondering how actual people can get the styles to fit as intended. Free shipping and returns are the only factors making online apparel purchases possible for many consumers who buy garments in multiple sizes with the intention of returning items that don’t fit. Unfortunately, the majority of these returns end up in landfills after winding their way through a network of resellers and racking up a giant carbon footprint along the way.

Body scanning finally offers a solution to the limited information available regarding body sizes and types. Not only can this tool become one of retailers’ key ecommerce conversion hacks, but it doubles up as a sustainable fashion technology that helps fashion to reduce its impact. With the information from these scans, businesses can create garments to fit different body types rather than depending on a proportional scale. The result is better fitting garments which lead to fewer returns, boosted conversion rate and improved accuracy and efficiency that could help reduce retail’s environmental footprint. Here is how digital body measurement process looks like with 3DLOOK solution:

On the consumer side, shoppers finally have the ability to understand how clothes will fit each one of their unique body shapes rather than being labeled an average. This increases confidence that what they buy will fit them and produces more loyal customers for brands and retailers.

5. Virtual Dressing

When consumers purchase clothing online or in the store, the only way to discover how the garment truly fits is to actually try it on. Unfortunately, the item often doesn’t offer the same fit as a model on the website or mannequin in the store. Essentially, trying on clothing to see whether it fits is little more than a data exchange. A consumer has a specific set of dimensions, and so does an item of clothing. Until recently, the cumbersome act of trying on multiple sizes was the only way to exchange this data.

Evolving 3D technology is making a radical change to the process, digitizing what used to be a very physical, manual process through an exchange of fit information via a digital platform. With thousands of data points to create a three-dimensional image, mobile 3D body scanning empowers consumers to immediately determine how clothes will fit them. Here is an example of virtual dressing from Farfetch in Snapchat.

Snapchat x Farfetch collaboration that allows users to try virtual clothes on via the camera.

Source: Forbes

The retailer, in turn, can compare consumer data going well beyond the traditional collar size, chest size, and sleeve length to include hundreds of measurements that make up the detailed dimensions of a particular garment. This will drive improved customer experiences by helping shoppers to find clothes they love with less effort. In addition, this technology also doubles up as a sustainable fashion innovation that can drastically reduce material waste and logistics emissions throughout the industry. As consumers take advantage of mobile body scanning products to better size online purchases, retailers can gather additional data to better understand body shape and create better fitting garments, driving down product return rates thanks to AR clothing try on solutions. Over the next five years as immersive technologies like AR, VR, and MR become pervasive, virtual dressing experiences will fuel the future of virtual shopping and introduce entirely new relationships for brand engagement.

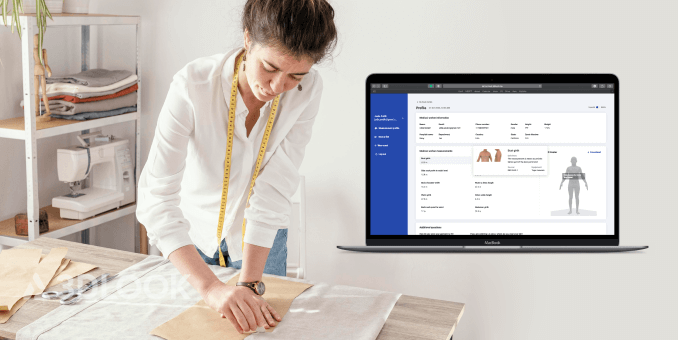

Yourfit

The first solution on the market to combine virtual try-on with size and fit recommendations. Pioneering brands using the solution have seen up to 48% decrease in return rates!

6. Making Fashion Circular

As consumers and retailers become more aware of the enormous amount of waste produced by the fashion industry new efforts are being made to avoid waste. Major brands including Burberry, Gap, H&M, Nike, and Stella McCartney have joined forces to support sustainable fashion by creating the Make Fashion Circular initiative.

The circular economy concept aims to design waste out of the product and manufacturing system keeping materials and products in use for as long as possible. This is accomplished by incorporating renewable materials and recycling old clothes into new ones.

Source: Ellen Macarthur Foundation

7. Re-commerce: Everything Old Is New Again

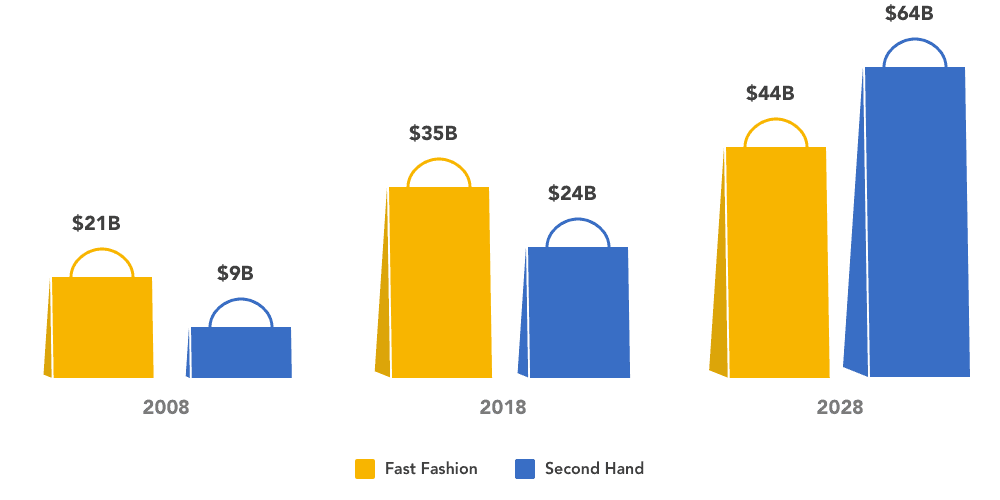

An estimated USD 500 billion value is lost every yeardue to clothing that’s barely worn and rarely recycled. Two techniques that combat this waste include upcycling and second-hand sales. While most people are familiar with Goodwill, other organizations are embracing the idea of selling gently used clothes as well. Online re-selling businesses like Poshmark, which doubled revenue from $1B to $2B in just one year, and Thredup have seen enormous growth over the last five years. Resale offers the wardrobe-rotating fun of fast fashion without guilt or waste, and it is estimated that secondhand will be larger than mainstream fast fashion within 10 years.

Upcycling is a term often related to personally crafting garments to create new ones. In the commercial fashion industry, upcycling is accomplished by recycling gently used fabrics or unsold inventory into new garments. According to figures from GlobalData Retail, 56 million women purchased second-hand items in 2018, representing a 27% jump from the year before. 51% of shoppers also reported that they plan to continue spending a greater share on resale goods in the next half-decade, the report outlined.

Ecommerce conversion hacks: How sustainable fashion tech can help to grow your sales

All fashion businesses should be searching for and implementing sustainable fashion innovations to reduce the industry’s environmental impact. Not just because it’s the ethical thing to do, but because it could be imperative to business success.

According to McKinsey, more than 60% of consumers consider environmental impact an important factor when making a purchase, while 66% are willing to pay more for sustainably produced products according to Neilsen. Particularly for online businesses, with the additional environmental cost of sky-high return rates, there is pressure to reduce waste and emissions. Therefore, embracing sustainable practices is considered among the top ecommerce conversion hacks for those looking to grow their online sales.

However, embracing digital transformation to avoid wasteful practices in the wider fashion industry is just as essential. As consumers become more environmentally conscious, major players in the industry are shifting away from the wasteful practices of the past and embracing sustainable fashion technology to help bring about major improvements. Making use of new 3D technologies and taking advantage of the digital transformation will benefit everyone in the supply chain, ultimately passing these benefits to consumers. To learn more about how sustainability is improving the fashion industry for retailers and consumers, contact 3DLOOK today.

Embracing emerging technology in the fashion industry can create a sustainable supply chain

Consumer desires aside, embracing digital transformation to avoid wasteful practices in the wider fashion industry is still essential. By implementing the various sustainable fashion innovations emerging, businesses throughout the industry can tackle costly issues such as overproduction, high return rates, poor consumer confidence and much more. Making use of new technology in fashion and taking advantage of digital transformation will benefit everyone in the supply chain, ultimately passing these benefits to consumers.

As consumers become more environmentally conscious, major players in the industry are shifting away from the wasteful practices of the past and embracing sustainable fashion technology to help bring about major improvements. To learn more about how sustainability is improving the fashion industry for retailers and consumers, contact 3DLOOK today.

Get in touch to learn how 3DLOOK’s mobile body scanning technology can help your business enhance customers’ shopping experiences by delivering better online fit experiences that are both engaging and personalized — while doing your part to support sustainable development in fashion industry.

Tags:

Fashion | sustainability | Technology

EXPLORE MORE CONTENT

Subscribe to our Newsletter

Offer your customers an entirely new, inclusive, and engaging way to interact with your brand

Offer your customers an entirely new, inclusive, and engaging way to interact

with your brand

Let us help you find the right solution for your business needs